What are the latest ceramic capacitors and equipment components procurement models?

What are the Latest Ceramic Capacitors and Equipment Components Procurement Models?

I. Introduction

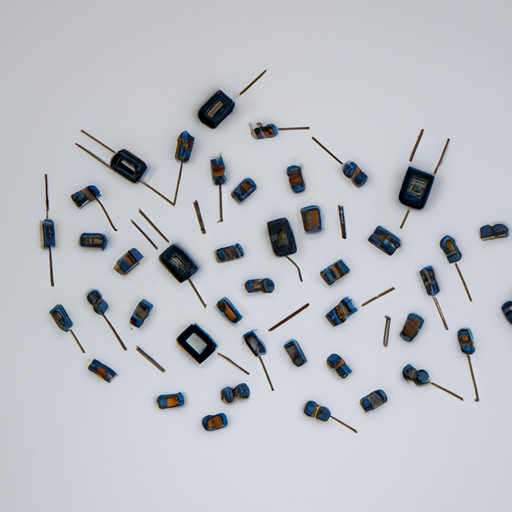

Ceramic capacitors are essential components in modern electronics, playing a critical role in various applications ranging from consumer electronics to automotive systems. These passive components store and release electrical energy, helping to stabilize voltage and power flow in circuits. As technology advances, the procurement models for these components are also evolving, reflecting changes in manufacturing processes, supply chain dynamics, and market demands. This blog post explores the latest trends in ceramic capacitors and the procurement models that are shaping the electronics industry.

II. Understanding Ceramic Capacitors

A. Types of Ceramic Capacitors

Ceramic capacitors are primarily categorized into two classes: Class 1 and Class 2 capacitors.

1. **Class 1 Capacitors**: These capacitors are known for their stability and low losses. They are typically used in applications requiring precise capacitance values, such as timing circuits and filters. The most common dielectric material for Class 1 capacitors is NP0 (C0G), which offers excellent temperature stability.

2. **Class 2 Capacitors**: In contrast, Class 2 capacitors, such as X7R and Y5V, provide higher capacitance values but with less stability and precision. They are often used in applications where size and capacitance are more critical than accuracy, such as decoupling and bypassing in power supply circuits.

B. Key Characteristics and Specifications

When selecting ceramic capacitors, several key characteristics must be considered:

1. **Capacitance Values**: Ceramic capacitors are available in a wide range of capacitance values, from picofarads (pF) to microfarads (µF), allowing designers to choose the right component for their specific needs.

2. **Voltage Ratings**: The voltage rating indicates the maximum voltage the capacitor can handle without breaking down. It is crucial to select a capacitor with a voltage rating higher than the maximum voltage in the application.

3. **Temperature Coefficients**: The temperature coefficient affects how capacitance changes with temperature. Different dielectric materials have varying temperature coefficients, impacting performance in temperature-sensitive applications.

C. Applications of Ceramic Capacitors

Ceramic capacitors are ubiquitous in modern electronics, with applications spanning various industries:

1. **Consumer Electronics**: From smartphones to laptops, ceramic capacitors are used in power management, signal filtering, and noise suppression.

2. **Automotive Industry**: In vehicles, these capacitors are essential for electronic control units (ECUs), infotainment systems, and safety features, where reliability and performance are paramount.

3. **Industrial Applications**: In industrial settings, ceramic capacitors are used in motor drives, power supplies, and automation systems, contributing to efficiency and reliability.

III. Trends in Ceramic Capacitor Technology

A. Advancements in Materials and Manufacturing Processes

Recent advancements in materials and manufacturing processes have significantly impacted ceramic capacitor technology.

1. **High-k Dielectrics**: The development of high-k dielectric materials allows for higher capacitance values in smaller packages, enabling miniaturization in electronic devices.

2. **Miniaturization and Surface-Mount Technology (SMT)**: The trend towards smaller and more compact electronic devices has driven the adoption of SMT, which allows for efficient use of space on printed circuit boards (PCBs).

B. Performance Improvements

The performance of ceramic capacitors has improved dramatically, with manufacturers focusing on:

1. **Enhanced Reliability and Stability**: New manufacturing techniques have led to capacitors with improved reliability, reducing the risk of failure in critical applications.

2. **Higher Capacitance in Smaller Packages**: Innovations in design and materials have enabled the production of capacitors with higher capacitance values in smaller form factors, meeting the demands of modern electronics.

C. Environmental Considerations

As environmental regulations become more stringent, manufacturers are focusing on:

1. **RoHS Compliance**: The Restriction of Hazardous Substances (RoHS) directive limits the use of certain hazardous materials in electronic products, prompting manufacturers to develop compliant ceramic capacitors.

2. **Lead-Free Soldering**: The shift towards lead-free soldering processes has influenced the design and materials used in ceramic capacitors, ensuring compatibility with modern manufacturing practices.

IV. Procurement Models for Ceramic Capacitors

A. Traditional Procurement Models

Traditionally, procurement models for ceramic capacitors have included:

1. **Direct Purchasing from Manufacturers**: Many companies purchase capacitors directly from manufacturers to ensure quality and reliability.

2. **Distributors and Wholesalers**: Distributors and wholesalers play a crucial role in the supply chain, providing access to a wide range of products and facilitating smaller orders.

B. Emerging Procurement Models

As the industry evolves, new procurement models are emerging:

1. **Just-in-Time (JIT) Procurement**: JIT procurement minimizes inventory costs by ordering components only as needed, reducing waste and improving cash flow.

2. **E-Procurement Platforms**: Online platforms streamline the procurement process, allowing companies to compare prices, manage orders, and track deliveries more efficiently.

3. **Collaborative Procurement**: Companies are increasingly collaborating to leverage collective buying power, reducing costs and improving supplier relationships.

C. Factors Influencing Procurement Decisions

Several factors influence procurement decisions in the electronics industry:

1. **Cost Considerations**: Price remains a critical factor, with companies seeking competitive pricing without compromising quality.

2. **Lead Times and Inventory Management**: Efficient inventory management and shorter lead times are essential for maintaining production schedules and meeting customer demands.

3. **Supplier Reliability and Quality Assurance**: Companies prioritize suppliers with a proven track record of reliability and quality, ensuring that components meet stringent performance standards.

V. Equipment Components Procurement Models

A. Overview of Equipment Components in Electronics Manufacturing

In addition to ceramic capacitors, various equipment components are essential in electronics manufacturing, including resistors, inductors, and integrated circuits. The procurement of these components is critical for maintaining production efficiency and product quality.

B. Traditional vs. Modern Procurement Strategies

Procurement strategies for equipment components have evolved:

1. **Long-Term Contracts vs. Spot Buying**: While long-term contracts provide stability and predictability, spot buying allows companies to take advantage of market fluctuations and secure better prices.

2. **Vendor-Managed Inventory (VMI)**: VMI involves suppliers managing inventory levels, ensuring that companies have the necessary components on hand without overstocking.

C. Role of Technology in Procurement

Technology plays a significant role in modern procurement:

1. **Supply Chain Management Software**: Advanced software solutions help companies manage their supply chains more effectively, improving visibility and coordination.

2. **Data Analytics for Demand Forecasting**: Data analytics tools enable companies to forecast demand accurately, optimizing inventory levels and reducing costs.

VI. Case Studies

A. Successful Implementation of New Procurement Models

1. **Example from the Consumer Electronics Sector**: A leading smartphone manufacturer adopted a JIT procurement model, significantly reducing inventory costs and improving cash flow while maintaining product quality.

2. **Example from the Automotive Industry**: An automotive supplier implemented a collaborative procurement strategy, pooling resources with other companies to negotiate better pricing and improve supplier relationships.

B. Lessons Learned and Best Practices

These case studies highlight the importance of flexibility and adaptability in procurement strategies. Companies that embrace new models and technologies are better positioned to respond to market changes and customer demands.

VII. Challenges in Procurement

Despite advancements, several challenges persist in the procurement of ceramic capacitors and equipment components:

A. Supply Chain Disruptions

Global events, such as pandemics and geopolitical tensions, can disrupt supply chains, leading to delays and increased costs.

B. Quality Control Issues

Ensuring consistent quality across suppliers remains a challenge, necessitating robust quality assurance processes.

C. Regulatory Compliance and Environmental Concerns

Navigating complex regulatory environments and meeting environmental standards can complicate procurement efforts.

VIII. Future Outlook

A. Predictions for Ceramic Capacitor Technology

The future of ceramic capacitors looks promising, with continued advancements in materials and manufacturing processes expected to drive performance improvements and miniaturization.

B. Evolving Procurement Models in Response to Market Demands

As market demands evolve, procurement models will continue to adapt, with a focus on efficiency, cost-effectiveness, and sustainability.

C. The Impact of Global Trends on Procurement Strategies

Global trends, such as the push for sustainability and the rise of digital transformation, will shape procurement strategies in the coming years.

IX. Conclusion

In conclusion, ceramic capacitors are vital components in modern electronics, and the procurement models associated with them are evolving rapidly. As technology advances and market demands change, companies must adapt their procurement strategies to remain competitive. By embracing new models and leveraging technology, businesses can optimize their supply chains, reduce costs, and ensure the reliability of their products. The future of ceramic capacitors and procurement strategies is bright, with opportunities for innovation and growth on the horizon.

X. References

- Academic journals and articles on ceramic capacitor technology and procurement models.

- Industry reports and white papers detailing trends in electronics manufacturing.

- Manufacturer and supplier websites for the latest product offerings and specifications.

This comprehensive overview provides insights into the latest developments in ceramic capacitors and the evolving procurement models that support the electronics industry. By understanding these trends, companies can make informed decisions that enhance their competitiveness and drive innovation.